AB BIOLOGICAL WASTEWATER TREATMENT PLANT

American Bottoms Regional Wastewater Treatment Facility is located in Sauget, Illinois. The plant provides preliminary, primary, and secondary treatment for wastewater from the city of East St. Louis and the city of Cahokia Heights. The plant also provides secondary treatment for all industrial and residential wastewater from the Village of Sauget, which has undergone preliminary and primary treatment at the Sauget Physical/Chemical Wastewater Treatment Plant. The American Bottoms Wastewater Treatment Facility was constructed in 1986 and is designed to treat an average of 27 million to a maximum of 52 million gallons of wastewater each day.

AB Preliminary Treatment:

The pump stations are located in the city of East St. Louis and in the city of Cahokia Heights. Gates control and direct the flow of wastewater from the collection system to barscreens that remove the large trash and debris. Both pump stations are equipped with mechanical barscreens that are raked automatically. The rakes pull the trash and debris up and out of the barscreens and drop it into a dumpster for disposal at a landfill. Wastewater flows from homes, businesses, and storm drains through a system of pipes to two pump stations located outside of American Bottoms. First, we remove large trash and debris. Industrial grade screens catch this debris and remove things like cans, bottles, plastic bags, lawn clippings, and all the things you might see in the gutters along the streets. Once this trash is removed, the wastewater is pumped from these pump stations through underground pipes to our American Bottoms plant.

The pump stations are located in the city of East St. Louis and in the city of Cahokia Heights. Gates control and direct the flow of wastewater from the collection system to barscreens that remove the large trash and debris. Both pump stations are equipped with mechanical barscreens that are raked automatically. The rakes pull the trash and debris up and out of the barscreens and drop it into a dumpster for disposal at a landfill. Wastewater flows from homes, businesses, and storm drains through a system of pipes to two pump stations located outside of American Bottoms. First, we remove large trash and debris. Industrial grade screens catch this debris and remove things like cans, bottles, plastic bags, lawn clippings, and all the things you might see in the gutters along the streets. Once this trash is removed, the wastewater is pumped from these pump stations through underground pipes to our American Bottoms plant.

Once through the barscreens, the wastewater is pumped to American Bottoms through a 42 inch force main from the East St Louis pump station and a 20 inch force main from the Cahokia pump station. These pipe lines join together just before entering the primary treatment process. The East St. Louis pump station contains four dry pit pumps, and the Cahokia pump station contains three dry pit pumps designed to convey the wastewater to American Bottoms.

AB Primary Treatment:

Clarifiers are big, round, deep, cement tanks. These tanks have a long arm that rotates from the center of the tank and skims across the surface much like the minute hand of a clock. Heavy solids, such as sand, settle to the bottom of the tank while floating solids, such as grease and oil, are removed by the rotating arm at the top of the clarifier. All solids removed from the clarifier are ground to a uniform size and sent to the gravity thickeners in the sludge handling process. After the Preliminary Treatment is complete at our pump stations, the wastewater is ready for Primary Treatment involving clarifiers.

Clarifiers are big, round, deep, cement tanks. These tanks have a long arm that rotates from the center of the tank and skims across the surface much like the minute hand of a clock. Heavy solids, such as sand, settle to the bottom of the tank while floating solids, such as grease and oil, are removed by the rotating arm at the top of the clarifier. All solids removed from the clarifier are ground to a uniform size and sent to the gravity thickeners in the sludge handling process. After the Preliminary Treatment is complete at our pump stations, the wastewater is ready for Primary Treatment involving clarifiers.

As new wastewater enters the center of the clarifier, the cleaner water flows out over the edge to a main channel. Wastewater leaving the clarifier eventually combines with the treated wastewater from our PChem plant for secondary treatment.

As new wastewater enters the center of the clarifier, the cleaner water flows out over the edge to a main channel. Wastewater leaving the clarifier eventually combines with the treated wastewater from our PChem plant for secondary treatment.

The main purpose of primary treatment is to settle out heavy solids. American Bottoms has four clarifiers designed for an average daily flow of 16.1 million gallons and a peak daily flow of 37.8 million gallons. The wastewater spends 5 – 6 hours in the primary treatment process where about 50-65 percent of the heavy solids are removed. Once the heavy solids fall to the bottom, they are referred to as sludge. Angled rakes rotating around the bottom push sludge to the center where it is removed and pumped to thickening tanks. The sludge passes through a grinder prior to entering the pump in order to grind the material collected into a smaller uniform size. This prevents any large material from plugging the pumping system and allows the sludge to more easily settle and thicken in the gravity thickeners. The floating scum and grease removed from the clarifiers is also sent directly to the gravity thickeners.

AB Secondary Treatment:

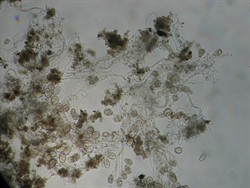

The main purpose of Secondary Treatment is to remove dissolved organics from the wastewater. This begins in large, open, rectangular aeration tanks where ammonia and organic matter are removed from the incoming wastewater by microorganisms commonly referred to as “bugs.” Our “bugs” are good “bugs” and a vital element of the treatment process. They are the primary means of removing pollutants that could potentially harm the environment. The contents of the aeration tanks look thick and watery, kind of like runny oatmeal, but it is oatmeal full of our great “bugs!” Air is supplied to the tanks to provide oxygen to the bugs which enables them to survive.

The main purpose of Secondary Treatment is to remove dissolved organics from the wastewater. This begins in large, open, rectangular aeration tanks where ammonia and organic matter are removed from the incoming wastewater by microorganisms commonly referred to as “bugs.” Our “bugs” are good “bugs” and a vital element of the treatment process. They are the primary means of removing pollutants that could potentially harm the environment. The contents of the aeration tanks look thick and watery, kind of like runny oatmeal, but it is oatmeal full of our great “bugs!” Air is supplied to the tanks to provide oxygen to the bugs which enables them to survive.

The secondary treatment process at American Bottoms is known as an activated sludge process because it consists of a biological method of treatment. The secondary process at American Bottoms is designed for an average daily flow of 27 million gallons and a peak daily flow of 52 million gallons. In this process, natural forming microorganisms will break down the dissolved organics in the wastewater. The microorganisms will colonize and form organic solids as they break down the organics which enables them to settle out in clarifiers downstream of the aeration tanks. The microorganisms require oxygen and constant water mixing in order to break down the dissolved organics. The needed oxygen enters the tanks through diffusers lining the bottoms of the aeration tanks. American Bottoms contains eight tanks in the activated sludge process. Six of these tanks are fully aerated for breaking down dissolved organics and ammonia to nitrates. The other two contain no air in order to break down the nitrates to nitrogen gas and complete the ammonia removal process.

The removal of ammonia in the activated sludge process is called nitrification and denitrification. These processes are very important at American Bottoms due to the large amounts of ammonia coming from industrial wastewater. Nitrification occurs in the aerated portion of the activated sludge process. Denitrification occurs in the non-aerated portion of the activated sludge process. The nitrification process can cause the water to become slightly acidic as ammonia is broken down into nitrates. When this occurs, lime is added to the water in order to neutralize it. A high percentage of water exiting the aeration tanks is returned by pumps to the tanks with no air to enable dentirifcation to occur.

The removal of ammonia in the activated sludge process is called nitrification and denitrification. These processes are very important at American Bottoms due to the large amounts of ammonia coming from industrial wastewater. Nitrification occurs in the aerated portion of the activated sludge process. Denitrification occurs in the non-aerated portion of the activated sludge process. The nitrification process can cause the water to become slightly acidic as ammonia is broken down into nitrates. When this occurs, lime is added to the water in order to neutralize it. A high percentage of water exiting the aeration tanks is returned by pumps to the tanks with no air to enable dentirifcation to occur.

After spending time with our “bugs” in the aeration tanks, the wastewater proceeds to secondary clarifiers for removal of the organic solids. Here, solids once again settle to the bottom of the tank. The sludge which has settled to the bottom is removed and either recycled or sent to the sludge handling process. The recycled sludge, or return activated sludge (RAS), is returned to the beginning of the aeration process in order to keep enough healthy, hungry “bugs” in the system to continue cleaning the wastewater.

American Bottoms contains four secondary clarifiers. Occasionally, a chemical is added to the wastewater coming from the aeration tanks to help the solids stick together for better settling. The sludge on the bottom of the clarifier is pulled through a pipe structure mounted to the rotating arm like a vacuum and is either pumped back into the aeration process or pumped to the gravity thickeners for sludge processing. Generally, most of the sludge is returned back to the aeration tanks. The RAS helps to maintain the concentration of microorganisms in the aeration tanks for the biological process. The remaining sludge is pumped to the gravity thickeners. This sludge is known as waste activated sludge, or WAS.

American Bottoms contains four secondary clarifiers. Occasionally, a chemical is added to the wastewater coming from the aeration tanks to help the solids stick together for better settling. The sludge on the bottom of the clarifier is pulled through a pipe structure mounted to the rotating arm like a vacuum and is either pumped back into the aeration process or pumped to the gravity thickeners for sludge processing. Generally, most of the sludge is returned back to the aeration tanks. The RAS helps to maintain the concentration of microorganisms in the aeration tanks for the biological process. The remaining sludge is pumped to the gravity thickeners. This sludge is known as waste activated sludge, or WAS.

Meanwhile, the clean water, or effluent, leaves the secondary clarifiers and flows through a water chute, called a flume, which measures the amount of water leaving our plant. Samples of the effluent water are taken at this location and monitored by the plant’s certified laboratory to ensure compliance. The water flows through a 60 inch diameter pipe to the effluent pump station. Once it reaches the effluent pump station, the treated water is either gravity fed or pumped to the Mississippi River through a 72 inch diameter pipe. The treated water is discharged into the Mississippi River through a diffuser pipe over 200 feet long that extends into the river. This allows the water to be distributed throughout the river.

Sludge Handling:

At the same time as the wastewater is treated, we’re getting the solids, or sludge, ready for disposal. The first step in the sludge handling process is the Thickening Process. Sludge, removed from the primary and secondary clarifiers, is pumped into thickeners where it settles and thickens further. American Bottoms has two primary thickeners and two secondary thickeners. Sludge from the secondary clarifiers is sent to the secondary thickeners. Sludge from the primary clarifiers, scum from both primary and secondary clarifiers, and thickened sludge from the secondary thickeners are all sent to the primary thickeners. Thickened sludge then moves to the dewatering stage.

Here it’s conditioned with chemicals in a conditioning tank for easier separation of water and solids. Next, the conditioned sludge passes through one of three belt filter presses where it is squeezed to remove as much water as possible. The dewatered sludge, or filter cake, is removed from the belt with scrapers where it falls to a conveyor and is conveyed to one of two sludge storage bins. Trucks are loaded from the storage bins, and the material is hauled to a landfill for disposal.

Laboratory:

Throughout the entire treatment process, samples are taken of the wastewater and sludge for testing in our on-site laboratory. Our American Bottoms laboratory has been accredited by the Environmental Protection Agency since 2002. On average, our lab analyzes nearly 10,000 samples of wastewater and solids every year.

Laboratory testing is vital to our operations and for compliance. The results of these tests are used to monitor Illinois Environmental Protection Agency permit conditions, to properly operate the treatment facility, and for troubleshooting.

We at American Bottoms continuously look for the best ways to produce a high quality wastewater effluent, be compliant, remain a safe place to work, and provide cost effective, beneficial services for our customers. Every one of our employees knows that treating wastewater is our primary responsibility for the protection of our nation’s water resources both today and for future generations.